Advanced Manufacturing Solutions

From Prototype to Mass Production

State-of-the-art SMT assembly, automated production lines, and rigorous quality control deliver flawless electronics manufacturing at any scale—from prototypes to millions of units.

Will Sparrow Technologies

Pioneering the Future of e-Manufacturing

Advanced Precision Engineering

Ultra-precise machining capabilities with tolerances down to ±0.0001 inches for aerospace and medical industries.

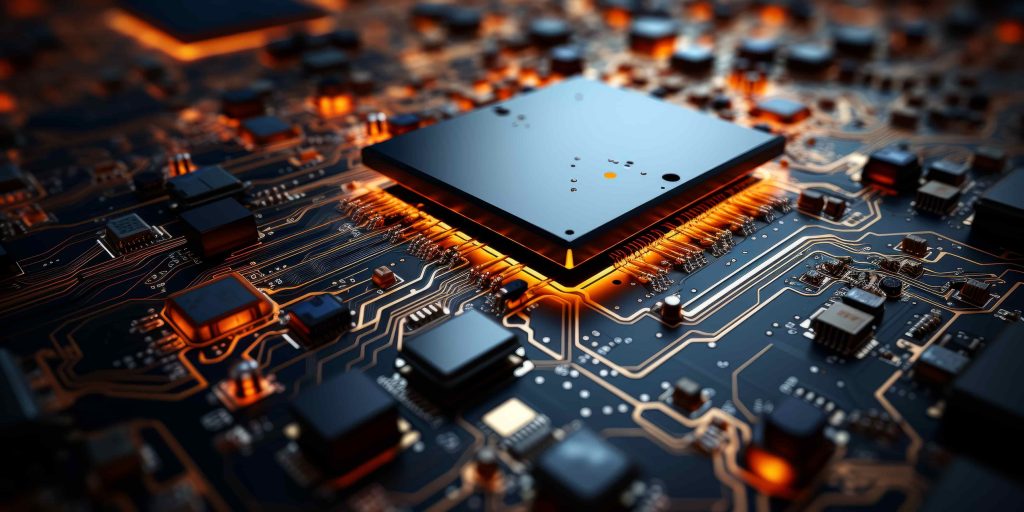

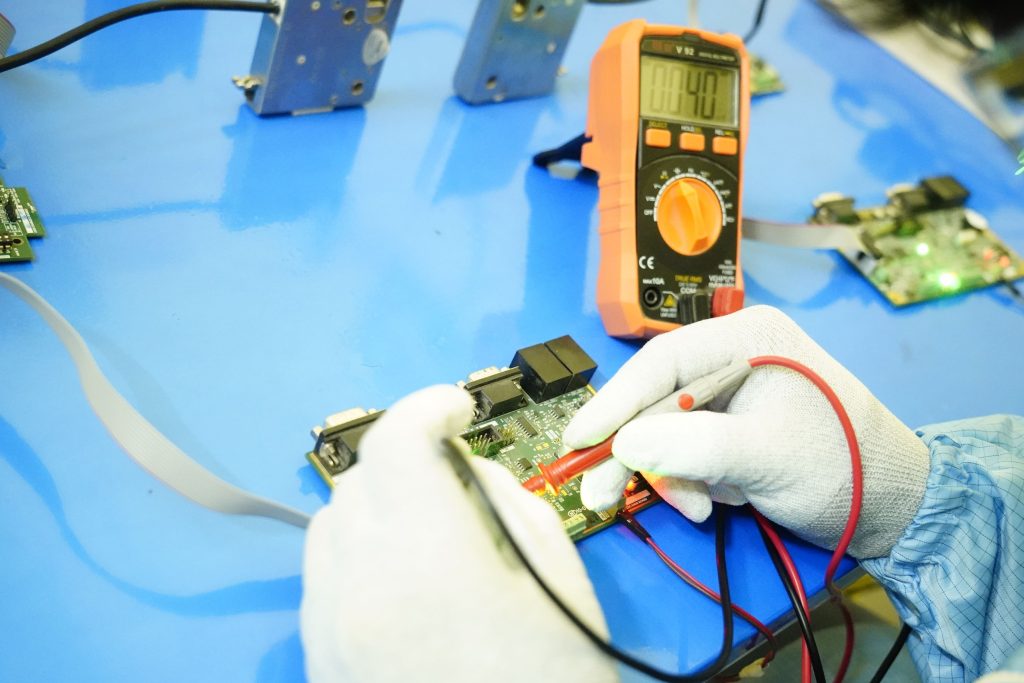

Smart Electronics Manufacturing

State-of-the-art SMT lines and automated testing for high-reliability electronic assemblies.

Robotic Automation Systems

Custom robotics and automation solutions increasing efficiency by up to 300% in production lines.

Quality Assurance Excellence

ISO 9001:2015 certified processes with advanced CMM and vision inspection systems.

Our e-Manufacturing Services

Comprehensive solutions for all your Manufacturing needs

PCB Assembly

High-quality PCB assembly solutions tailored to your needs. From prototypes to production, we ensure precision, reliability, and rapid delivery at every stage.

EMS Solutions

Comprehensive EMS services, including SMT and through-hole assembly, with rigorous quality control through automated optical and X-ray inspections.

Box Build & Integration

Comprehensive box build solutions including enclosure assembly, wiring, and final product integration for end-to-end manufacturing support.

Prototype Fabrication

Fast and precise prototype fabrication to help validate designs and accelerate your product development timeline.

RMA & Logistics

Streamlined RMA processes and logistics support to manage returns, repairs, and replacements reliably.

PCB Layout

Expert PCB layout services to optimize performance, ensure manufacturability, and meet specific project requirements.

Quality Assurance

Advanced QA procedures to ensure every product meets rigorous industry standards for performance and reliability.

BGA Rework

Specialized BGA rework services using advanced reflow and reballing techniques to ensure precise and reliable repairs.

Defect Detection

Advanced defect detection systems using automated inspection technologies to ensure flawless production quality.

Manufacturing Capabilities

Transforming Precision Engineering into Technological Marvels

Fine Pitch Assembly

Expert precision in assembling 01005/0201 components with unrivaled accuracy.

High Accuracy Placement

Ultra-precise device integration with placement accuracy down to 0.2mm pitch.

Flex Circuit Assembly

Expert handling of flexible circuit boards with advanced manufacturing techniques.

Sequential Assembly

Systematic board bring-up process ensuring consistent quality and reliability.

BGA & uBGA Services

Advanced Ball Grid Array placement, re-balling, and precise rework capabilities.

X-Ray Inspection

High-intensity X-Ray inspection ensuring complete component integrity and quality.

Our Advanced Facilities

Cutting-edge technology and precision engineering for exceptional electronic manufacturing

Packaging Capabilities

Advanced handling of 0201 to IC, QFP, QFN, BGA, CSP’s with precision (Up to 0.2mm pitch)

Rework Stationss

State-of-the-art rework stations for precise electronic component modifications

Thermal Management

Advanced baking oven and thermal chamber for optimal component processing

Our PCB Assembly Capabilities

Wills Sparrow’s roots lie in the assembly and testing of printed circuit boards. Today we support high-low mix with low-medium-high volume solutions to a customer base of more than 250 customers.

Our production lines are compatible with all currently available component technologies and are ideal for assembly of both large and small series. Our manufacturing facility accommodates both automated and manual assembly of PCBs and online testing. Our surface mounting PCB assembly lines are best suited for component technologies like 01005, QFP, QFN, BGA, micro-BGA, etc. With continuous improvisation, and the flexible nature of our manual assembly lines, we ensure that our customers’ changing needs are satisfied.

With our proven experience with advanced lead-free manufacturing processes, we are able to cater to various high-skilled rework matters which pertain to verticals such as defense, aerospace, telecommunications, and so on.

Wills Sparrow is a full-service PCB assembly company that specializes in PCB assembly. We offer top-of-the-line printed circuit board assembly using SMT surface mount assembly, through-hole assembly, and more. We even offer professional box build assembly services.

Our System Assembly Capabilities

1

Prototype Builds

2

Pre-production Builds

3

Build To Order (BTO)

4

Configure To Order (CTO)

5

Build to Standard Configurations

6

High Complexity System Design Integration

Electronic Manufacturing Services (EMS)

Discover the advantages of precise valuations, local expertise, and personalized service.

Comprehensive End-to-End EMS Solutions

Wills Sparrow is an EMS that provides complete end to end solutions to its customers including plastic molding, functional testing after complete integration and complete box builds.

Expert Procurement

The procurement teams work closely with the customer to ensure total customer satisfaction. The procurement team includes highly skilled professionals with rich experience of more than 10 years individually.

Efficient SCM

The SCM team works through an ERP system and a modern inventory management method providing cost effective solutions to the customer with the ultimate objective of customer satisfaction in mind.

Global Vendor Network

The department has a very wide vendor base spread across Asia, Europe and USA.

Full Systems Build / Integration

Wills sparrow provides a comprehensive range of full Box Build and Integration solution from simple PCBA in to enclosure to complex chassis & wiring assemblies, final equipment manufacture and product encapsulation. Our services include full Functional and Soak test meeting the requirements of a varied number of applications and market sectors.

Wills sparrow capability includes a full test and repair service utilizing either customer supplied or in house developed test solutions supporting the product for the entire life cycle.

Quality and Reliability Services

Quality itself has been defined as fundamentally relational: ‘Quality is the ongoing process of building and sustaining relationships by assessing, anticipating, and fulfilling stated and implied needs. Keeping in mantra in mind, it has always been Wills sparrow ’s endeavour to ensure our customers are delivered quality compliant products.