What is E-Manufacturing?

E-Manufacturing (Electronic Manufacturing) encompasses our comprehensive suite of electronic design, prototyping, assembly, and production services. From initial concept to final product delivery, we provide end-to-end solutions for your electronic manufacturing needs.

Pioneering the Future of e-Manufacturing

Will Sparrow Technologies

Our E-Manufacturing Process

Quote & Design Review

24-48 hour quote turnaround

Prototyping

Rapid prototype in 24-48 hours

Production

Scalable from 1 to 10,000+ units

Quality & Delivery

Full testing & worldwide shipping

Advanced Precision Engineering

Ultra-precise machining capabilities with tolerances down to ±0.0001 inches for aerospace and medical industries.

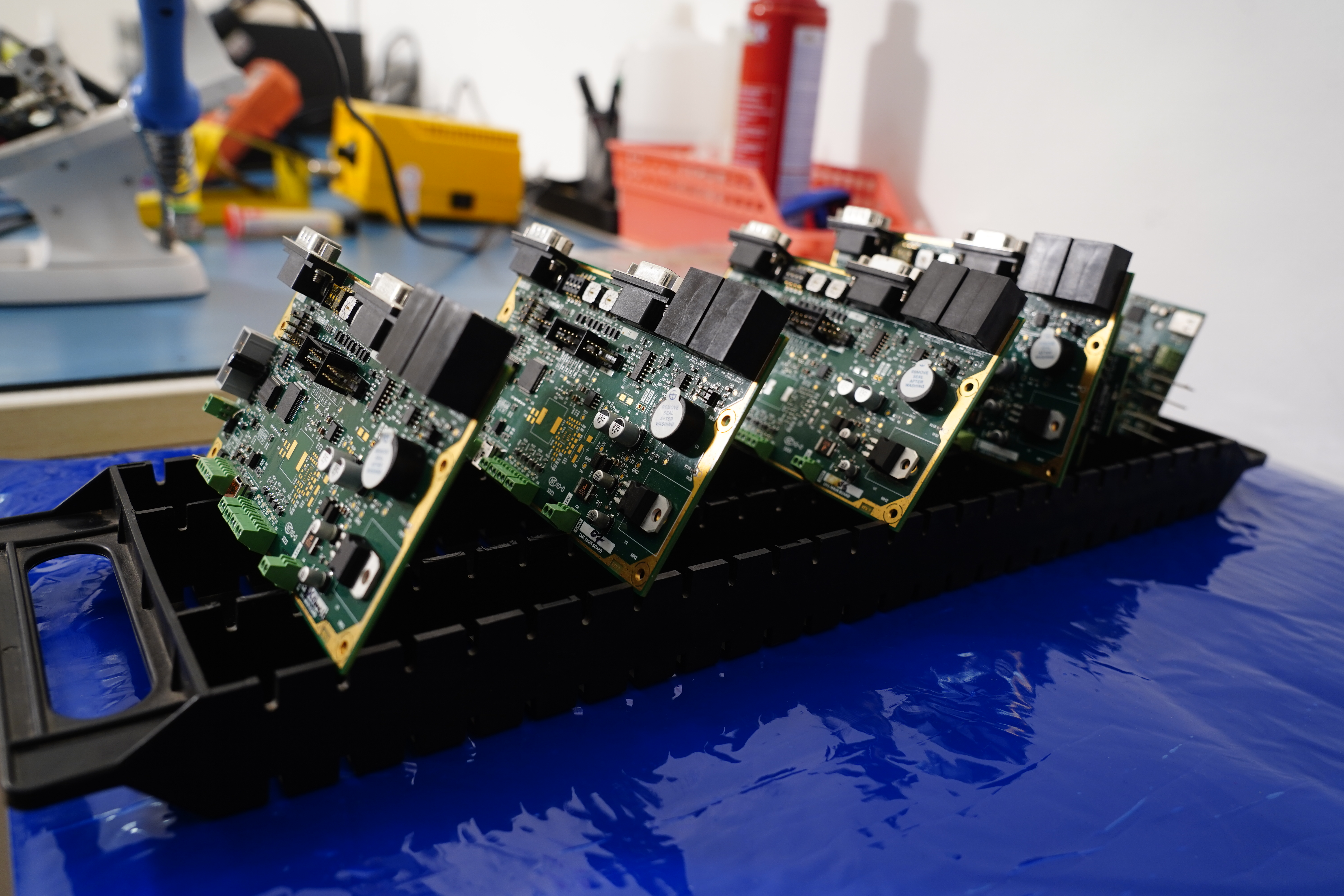

Smart Electronics Manufacturing

State-of-the-art SMT lines and automated testing for high-reliability electronic assemblies.

Robotic Automation Systems

Custom robotics and automation solutions increasing efficiency by up to 300% in production lines.

Quality Assurance Excellence

ISO 9001:2015 certified processes with advanced CMM and vision inspection systems.

Pricing & Timeline Information

Quote Process

- • Free quote within 24-48 hours

- • Send files to: quotes@willsparrow.com

- • Include quantity & timeline requirements

- • DFM feedback included

Minimum Orders

- • Prototypes: 1 piece minimum

- • Small batch: 5-100 pieces

- • Production: 100+ pieces

- • Volume discounts available

Lead Times

- • Rush prototypes: 24-48 hours

- • Standard prototypes: 3-5 days

- • Small batch: 1-2 weeks

- • Production runs: 2-4 weeks

File Requirements & Specifications

Accepted File Formats

- • Gerber files (RS-274X)

- • Excellon drill files

- • Pick & place files (CSV/TXT)

- • Bill of Materials (BOM)

- • Assembly drawings (PDF)

- • 3D files (STEP, IGES)

Technical Specifications

- • Board size: 0.75" x 0.75" to 14.5" x 19.5"

- • Layers: 1-32 layers

- • Component size: 01005 to large BGAs

- • Pitch capability: Down to 0.2mm

- • Lead-free & RoHS compliant